Bentley Applications Helped Determine How to Establish Renewable Energy in the Area while Saving Time and Money.

China has been a world leader in renewable energy growth, accounting for 40% of the world’s renewable energy development from 2015 to 2020.

The country works to shift away from fossil fuels by instituting corporate mandates and directing the People’s Bank of China to provide low-cost funding to lenders that contribute to green projects. The objective is to generate a combined 1,200 gigawatts of wind and solar energy by 2030.

China wants to transition a full 80% of its energy mix to renewables by 2060. To help meet the country’s goals, POWERCHINA Hubei Electric Engineering undertook the design and construction of an 80-megawatt ground-based photovoltaic power station near Guangshui in the Hubei province.

The design team soon ran into several challenges while developing in the region, which is dominated by hills, pine woods, and fishponds. They had to carefully choose a location that could accommodate 14,080 solar panels while minimizing the impact on the environment and local wildlife.

Once the site was selected, they would then have to optimize the design of the photovoltaic array, booster station, access road, and transmission line to suit the widely varying topography of the area.

Specifically, the design would need to shorten the length of the road, reduce the size of the booster station, and maximize the daily amount of electricity generated by each component. Even with the demands of the project, POWERCHINA Hubei still had to carefully control costs.

Struggling with Inadequate Software

POWERCHINA Hubei determined that digital design would help them select the optimal location for the power station, and then place all components around the environment. They initially selected third-party design software for the job.

Within a short time, they learned that the complexities of the project overwhelmed their software. All potential sites for the station were covered in low hills and steep slopes, often with gullies and hollows between them.

As a result, they needed to modify supports for every one of the thousands of components for them to fit in the irregular terrain. Every solar panel needed a different angle and spatial position based on the ground elevation and the potential shading.

The considerable size of the facility, and the large number of solar panels, added up to a massive number of individual adjustments that were difficult to make in their previous software.

Adding to the problems, the design showed that the engineering quality of the cabling, from the individual panels to the booster station to the transmission line, was difficult to control. They opted to bury the cabling to protect them from regular wear and to lessen the ongoing impact to the environment.

Yet the undulating environment also made the cabling process difficult, and their original software was not able to help them ensure a suitable layout.

Though the team initially attempted to create the design of the entire power station in the initial software, it could not easily handle the large number of complex tasks and significantly slowed the process.

To avoid falling behind the project’s strict 10-month deadline, the team decided they needed to switch to a series of applications that would support their goals rather than get in their way.

Automating Solar Panel Placement on Complex Terrain

After a brief search, POWERCHINA Hubei determined Bentley’s applications would allow them to fully model the fine details of the complex project while meeting their deadline.

They began by using ProjectWise to create a connected data environment, enabling all contributors to collaborate on the design with the confidence that all information was up to date.

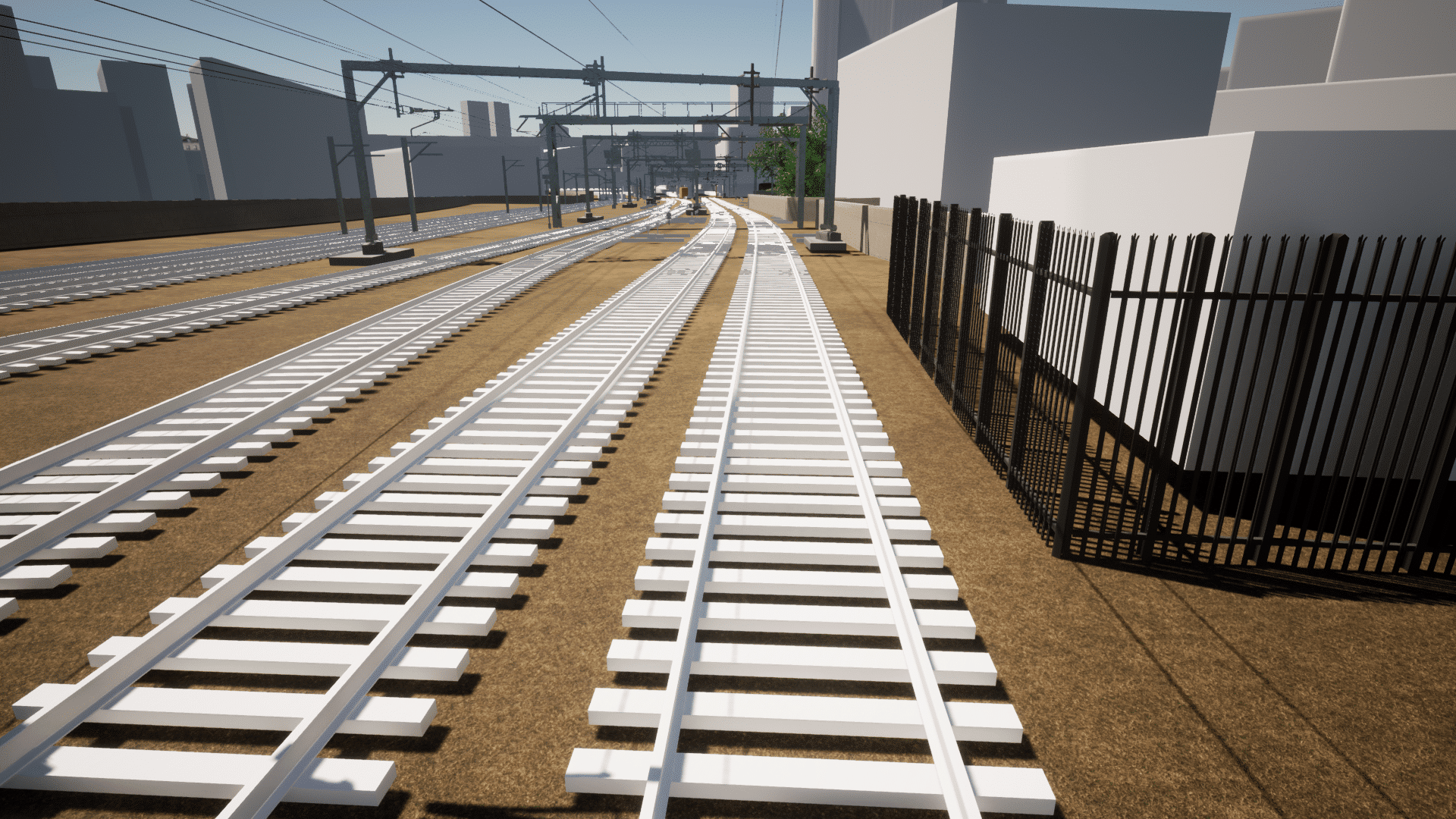

Next, they imported a reality mesh of the project environment into MicroStation and OpenBuildings, then performed a full terrain analysis to determine how to design and adjust individual components.

Using the applications, the team developed specific software that could help them quickly design solar fields in mountains.

Once they created base 3D models of the solar array, they used the software to automate the placement and angle of each of the 14,080 solar panels in and around the hills, keeping total shading on the project at any given time below 2% and guarantee maximum exposure to sunlight.

With the solar panels in place, POWERCHINA Hubei then used OpenBuildings Designer to design the booster station and OpenUtilities Substation to determine the cabling layout and design the transmission line.

With the help of OpenUtilities, they determined how to effectively bury the cables under the hills while minimizing the disruption to the area.

Lastly, with a completed digital twin of the entire development, they used SYNCHRO to determine the most efficient construction schedule possible, which helped them improve construction management.

Improving Construction with Clear Intent and Scheduling

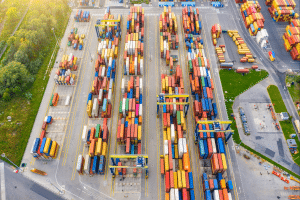

With the help of a digital twin created with Bentley applications, POWERCHINA Hubei optimized both the design and construction of the power station.

Integrating all elements into a federated model helped them discover how to shrink the footprint of the booster station to just 1,181 square meters and reduce the length of the access road by four kilometers.

Since the design team could automatically generate and place models within their digital twin, they saved CNY 1 million, compared to manually creating the elements. Their custom software for automating the placement and angle of solar panels kept panel shading below 2%, which maximizes daily electrical production.

Working within the single digital twin allowed the team to detect and resolve clashes that would have resulted in 40 instances of rework, which saved 20 days of construction and CNY 800,000.

They also reduced the amount of cabling needed due to careful planning within the digital model, which saved an additional CNY 600,000.

Throughout the development process, the digital model reduced design errors and the need for manual verification, resulting in a more efficient design. POWERCHINA Hubei then put the digital twin to work during construction with SYNCHRO 4D.

Planning every step of the process, using the 3D models to clearly communicate the design intent with contractors, and incorporating augmented reality technology accelerated construction by 30 days while avoiding any accidental panel shading.

“The project was an innovative application of mountainous photovoltaic projects in the new energy sector,” said Zhu Hanwei, secretary general of the Information Technology Working Committee, Exploration and Design Association of Hubei Province.

“It provided an excellent design scheme using complete solutions, and supported procurement and construction management using digital twin models, providing high-quality construction management.”

The power station is now operational and delivering renewable energy to Hubei. POWERCHINA Hubei subsequently worked with Bentley experts to establish the China Power Engineering Software Research and Development Center, which expands upon the techniques used in the Guangshui project and enhances the organization’s ability to offer integrated digital solutions across the lifecycles of future solar power stations.

Project Summary

Organization

POWERCHINA Hubei Electric Engineering Co., Ltd.

Solution

Utilities and Communications

Location

Guangshui, Hubei, China

Project Objectives

- To develop an 80-megawatt solar power station in hills of Hubei.

- To design around undulating terrain while keeping shading below 2%.

Products Used: iTwin.js, MicroStation, OpenBuildings, OpenRoads Designer, OpenUtilities Substation, SYNCHRO 4D

Fast Facts

- POWERCHINA Hubei needed to install 14,080 solar panels and associated components on land dominated by hills, woods, and fishponds.

- Their initial software was inefficient and became overwhelmed by the complex project.

- The design team determined they could optimize the design of the facility by creating a digital twin.

ROI

- Combining the Bentley digital twin model with POWERCHINA Hubei’s custom software kept panel shading below 2%, which maximizes daily electrical production.

- The digital twin helped detect and resolve clashes that would have resulted in 40 instances of rework, saving 20 construction days and CNY 800,000.

- Planning every construction step and using the 3D models to clearly communicate design intent accelerated construction by 30 days.

“The project was an innovative application of mountainous photovoltaic projects in the new energy sector. It provided an excellent design scheme using complete solutions, and supported procurement and construction management using digital twin models, providing high-quality construction management.” Zhu Hanwei, Secretary General of the Information Technology Working Committee, Exploration and Design Association of Hubei Province.