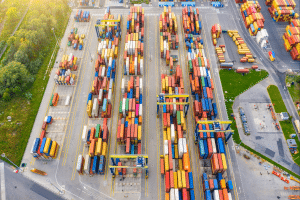

Supply chain management is a crucial aspect of the ever-evolving retail industry. Due to the massive disruptions caused by the recent pandemic, there has been a noticeable shift in supply chain management – from traditional, centralized models to more decentralized and agile networks.

To meet customer demand and to stay ahead of the competition, retailers need to have complete visibility of their supply chain network. This can be achieved by leveraging technologies such as Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), and Blockchain.

“Retailers are leveraging data to improve operations and offer a more personalized experience for customers,” Alan Boehme, CTO, H&M Group, Sweden said in a podcast.

“For example, if a shopper picks up a garment in the front of the store and takes it to a fitting room in the back of the store, we actually can see that garment moving and we can create brand new customer experiences or predict based on their purchase history or predict based on what they’ve picked up.”

By adopting these innovative technologies, retailers can achieve a higher level of efficiency and responsiveness in their supply chains. They can effectively monitor the location and condition of goods, optimize inventory levels, and ensure seamless transportation. Furthermore, these advancements enable retailers to forecast demand more accurately and make informed decisions, empowering them to meet customer expectations and maintain a competitive edge.

Here’s how geospatial and location play a role in supply chain management:

Warehouse & Inventory Management

With the growth of e-commerce, lack of clarity on stock levels and incorrect data on availability could lead to bottlenecks and delays in delivery. Geographic Information System (GIS) enables retailers to visualize all parts of their supply chain, from warehouse to transportation assets, and down to store inventory, all in one platform.

Indoor mapping of an entire warehouse can significantly improve stock visibility and the order picking process. With the help of AI, orders can be clustered logically, which helps optimize picking routes by warehouse employees. Such integrated, intelligent task planning also optimizes workload distribution for employees and helps prioritize more time-critical shipments. Similarly in a superstore, restocking shelves, finding and returning misplaced products, and tracking inventory levels are challenging tasks for store employees.

An integrated system of indoor positioning, IoT sensors, robotic scanners, and AI can be trained to detect items on the shelves, recognize the specific product types, and compare the quantities on the shelves to the predicted sales demand. The system then automatically triggers out-of-stock notifications to internal apps that alert store employees to re-stock particular items.

In the future, the current 2D capability will be further refined and replaced with 3D. “The advent of Augmented Reality (AR) will drive a nascent need for 3D data to map complex building structures, from the warehouse to the mall and down, one day, to the aisle and the shelf, in the store,” says Nick Zabikow, Senior Director of Sales, Logistics and Technology, HERE Technologies, USA.

Demand Prediction

Demand prediction helps retailers minimize stockouts, reduce excess inventory, and most importantly, ensure customer satisfaction. “Location data was not commercially available before 2015. So one of the most powerful recent capabilities is the creation of a historical database, i.e. the ability to monitor the change in consumer behavior over time,” says Yiannis Tsiounis, Ph.D., Executive Chairman, Advan Research, USA.

On top of historical sales data, customer behavior analysis, and market trends; special events such as holiday seasons and weather patterns also affect demands. Analyzing such data in a GIS can ensure accurate demand prediction by store location.

Another parameter that can be used to understand demand patterns, especially for supermarket chains, is the number of cars in the parking lots. Using archived high-resolution satellite data, automobile counts can be collected accurately and at the same time on specific days. When combined with other data, it can provide valuable snapshots of monthly sales activity at individual stores or trends among retail locations.

Shipment Tracking

Order fulfillment and shipping are the most critical components for retailers as they impact customer retention and profitability. Real-time shipment tracking utilizes GNSS-enabled telematics devices or Radio-frequency identification (RFID) tags, combined with logistics databases, to determine the position of any package at any moment in time.

Whenever a parcel is scanned, it gets assigned to a vehicle or a dispatcher, which position is constantly monitored via mobile devices. Such real-time location updates allow retailers to gain immediate visibility into the location, condition, and availability of products throughout the supply chain. Consequently, offers a more transparent delivery information to consumers.

“With better precision in tracking, routing algorithms will evolve; also using more and more complex datasets, the technology trends of routing, ETA calculations will move towards predictive analytics, helping a retailer and its operations centers be more proactive,” adds Zabikow.

Last-Mile & Hyperlocal Delivery

Last-mile delivery is a critical component of the entire retail supply chain. The goal of last-mile delivery is to deliver orders to consumers as quickly as possible.

Location Intelligence can help retailers reorganize information into its route planning algorithms or by reconfiguring distribution services for specified consumers’ locations. An efficient last-mile delivery will not only increase productivity but improve customer satisfaction and loyalty.

“Previously, people needed to travel to retail locations, whereas with the new trend, businesses now can rely on dark stores, logistics-wise optimized locations for effective shipments. Therefore address handling, geocoding, routing and optimization for deliveries are now more critical,” says Alim Küçükpehlivan, CEO, Basarsoft, Turkey.

Having a route optimization software powered by geospatial technology will help delivery drivers/riders determine the best routes to take based on real-time updates on traffic conditions, roadblocks and other incidents on the road. This capability will enable faster deliveries, save fuels and more profit as more deliveries can be made within a day.

The system can also be used to analyze late deliveries. By correlating delivery times and delays with variables such as building type, access type, and parking facilities, a new layer of delivery intelligence can be created on top of location data.

“In India, increasingly retail delivery and deliver-to-consumer location are becoming popular. All segments of retail are witnessing huge appetite for location intelligence. In addition to aggregators like Zepto, Swiggy, Instamart, Dunzo, BlinkIt, and Big Basket, big consumer brands and retail companies are also directly delivering to the customers through delivery/courier partners,” shares Aswani Akella, Founder, LatGeo Consulting, India.

“From urban areas, the services are now migrating to tier-2, tier-3 towns and rural areas. Interestingly, hyper-localized services and solutions are manifesting a behavioral shift in consumption patterns triggering demand for predictive and prescriptive analytics,” he adds.

In addition, many businesses across various industries use geocoding, which is converting street addresses into geographic coordinates. There has been a transition from range interpolation geocoding, which assumes locations for certain establishments, to Rooftop Geocoding, which indicates the exact location of the structure.

“This shift has resulted in greater location accuracy, leading to significant benefits for businesses,” says Jan Kestle, President and CEO, Environics Analytics, Canada.

In recent years, retailers such as Walmart, Amazon, and Domino’s Pizza have tested the use of automation for last-mile delivery. This includes drones, autonomous vehicles, and robots. Such unmanned and contactless deliveries require accurate geospatial and location capabilities to ensure delivery safety and efficiency.

ALSO READ: Location Intel for Marketing