Senior Assistant Editor

In April 2021 in the Netherlands, when United Nations climate officials congregated at the World Circular Economy Forum, their key conclusion was that shifting swiftly to a circular economy is essential to achieving the climate goals agreed on by the international community at the Paris Climate Agreement. This would also accelerate the process of rebuilding the world’s economies stronger, greener and better.

A circular economy, also called ‘circularity’, is an economic system that employs reuse, sharing, repair, refurbishment, remanufacturing, and recycling to create a closed-loop system, thereby minimizing the use of resource inputs and limiting waste, pollution, and carbon emissions. The idea of circularity is often linked to the UN Sustainable Development Goals (SDGs), and is accelerated by digital innovation.

The concept of a circular economy goes back to 1966, when American economist Kenneth E. Boulding wrote about the ‘cyclical’ system of production in his book titled The Economics of the Coming Spaceship Earth. The term circular economy first appeared in 1988 in a book called The Economics of Natural Resources. Over the years, the concept of circularity has evolved, and is widely discussed today due to the climate crisis facing our world.

As per a 2015 book titled Waste to Wealth by Accenture Strategy, a circular economy could generate $4.5 trillion of additional economic output by 2030. The book also suggests that advances in digital technologies will underpin the emergence of a circular economy. “While a number of pioneers have achieved successful examples of the circular economy, new digital technologies now offer an opportunity for all companies to put circular business models at the core of their global strategies,” writes Jakob Rutqvist, Senior Manager, Accenture Strategy, and co-author of Waste to Wealth. The same year, another report by WRAP and the Green Alliance titled Employment and the Circular Economy: Job Creation in a More Resource-efficient Britain examines different public policy scenarios leading up to 2030. The report states that with no policy change, nearly 200,000 new jobs will be created in the UK, reducing unemployment by 54,000; and a more aggressive policy scenario could create 500,000 new jobs and permanently reduce unemployment by 102,000.

In 2013, Towards the Circular Economy: Economic and Business Rationale for an Accelerated Transition, a report by the Ellen MacArthur Foundation and McKinsey & Company, highlighted the potential for significant benefits of the circular economy across the European Union (EU). It suggested that a subset of the EU manufacturing sector could realize net materials cost savings worth up to $630 billion annually by 2025 — stimulating economic activity in the areas of product development, remanufacturing, and refurbishment.

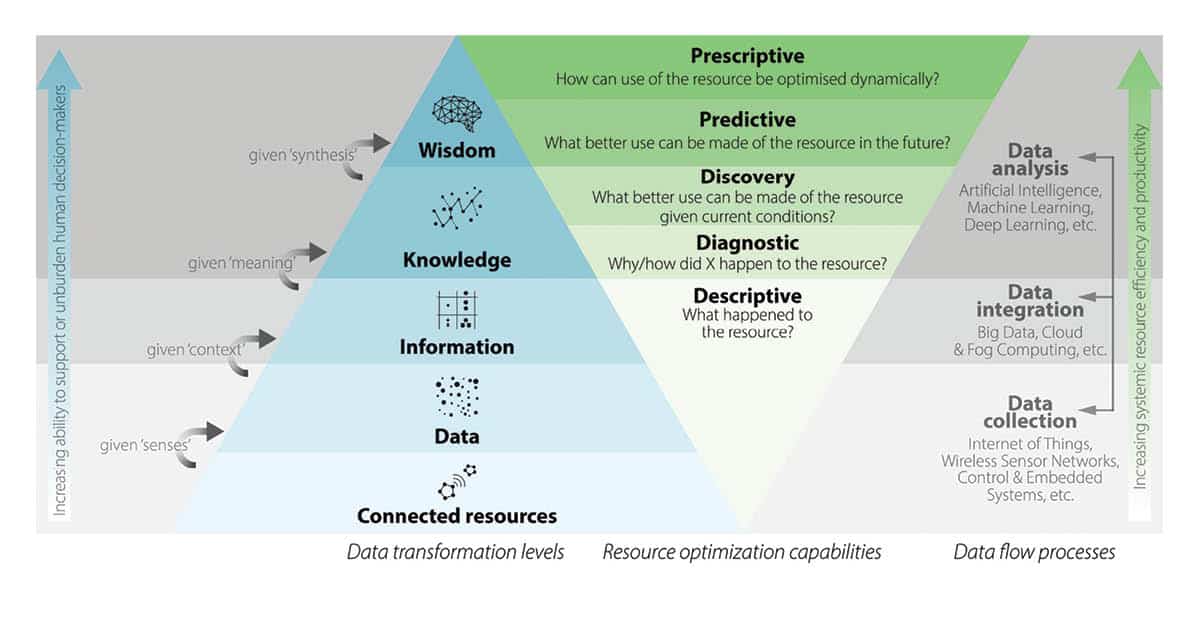

Digitalization is increasingly becoming a driving force behind a majority of industries. Since a circular economy aims to optimize resource use within sectors, there is a clear connection between the two. Modern-day digital technologies, such as the Internet of Things (IoT), Big Data, Artificial Intelligence (AI), and Blockchain are critical enablers for upscaling the circular economy. In March 2020, the European Commission adopted the new Circular Economy Action Plan (CEAP), which is one of the main building blocks of the European Green Deal — a strategy for sustainable growth. The crucial role of digital technologies in accelerating the transition to a circular economy is strongly emphasized in CEAP.

Geospatial technologies, including Geographic Information Systems (GIS) and Location Intelligence (LI) sit right at the heart of the circular economy, which requires products to be connected digitally to the manufacturer so that the entire product lifecycle can be monitored. The complex circular networks connecting suppliers and partners too need to be seamlessly managed, and geospatial technology, complemented by advances in digital technologies (especially the combination of mobile, machine-to-machine, and data analytics) plays a significant role in enabling circular economy practices.

Further, GIS maps can help reveal how many products are in use in a given area. As the number of products rises, marketing companies can initiate a buyback campaign — geo-targeted to a particular group of owners at specific phases of the ownership cycle. The rebought products can then be sold again or fed back into the production cycle as raw material for manufacturing new products. Also, organizations can share an intelligent map of recycling drop-off sites with customers via a website or mobile app. The New York City has taken this approach, showing residents locations where they can drop off several tons of the 200,000 tons of clothing they usually send to the landfill in an average year.

In 2018, SAP organized a design competition called the ‘Plastics Challenge’, to encourage the use of technology to eliminate single-use plastic waste. The project began with consumer research tracking the use of plastic of a few dozen UK citizens who were willing to share data around their daily engagement with plastics for a month. This data was used as a basis for a multi-day design thinking workshop with 25 large companies, including Coca-Cola, Visa, and Unilever, to develop solutions based on the reality facing consumers. The contest led to the development of a smartphone app that uses Machine Learning (ML) to help people identify different kinds of packaging materials. The phone’s geolocation service determines where to recycle the materials best, based on local programs. Another prototype embedded a chip in a reusable coffee cup to function as both a payment and loyalty rewards system, incentivizing cup reuse.

GIS maps can help reveal how many products are in use in a given area. As the number of these products rises, marketing managers of companies can initiate a buyback campaign — geotargeted to a particular group of owners at specific phases of the ownership cycle

The Asociacion de Cooperativas Argentinas (ACA), a farming organization in Argentina, developed an open digital platform for their farmers and suppliers to help produce more with less cost and environmental impact. The technology challenge was to create a system that could analyze multiple data sources in real time, gain visibility into each stage of farming, and deliver automatic recommendations to farmers. With geospatial data from satellites and drones, ACA can now monitor ambient soil conditions, indicating arable land’s potential productivity. This data can then be combined with other sources, such as weather and business data, to understand real-time requirements for farmers and make intelligent recommendations.

Lush Cosmetics tasked themselves with creating a waterless, signage and package-free shop. The company has developed a digital solution, the Lush Labs app, allowing customers to identify package-free products using Augmented Reality (AR). The app shows the user ingredients, benefits, and video demos. A feature called Lush Lens lets customers identify and learn about a product by taking a photo of it.

Similarly, Topolytics, a UK-based solutions provider, created an app for real-time tracking of waste flows in the country. The app is now also used in India and other countries. It uses radio-frequency identification (RFID) labels to track the movement of garbage via itemlevel digital identities. The system tracks waste from households, local authorities, businesses, and the construction sector. The data is analyzed along with other sources, including invoicing records, weighbridge and bin weighing systems, vehicle telematics, ‘internet of bins’ sensors, and intelligent labeling systems for an informed and holistic waste management strategy.

Just like geospatial, the Digital Twin technology significantly supports the transition towards a more circular economy. Accenture and Dassault Systèmes have partnered to advance the potential of digital twins. The result is a comprehensive report examining related use cases in several industries, including consumer goods, mobility, and construction. For example, Aden, an integrated facility management service provider, created a digital replica of one of its commercial centers in Chengdu, China. The twin monitors, aggregates, and analyzes data to plan and execute inspection, maintenance, and repair activities. Energy consumption under different operating conditions is predicted and optimized. Expected benefits include reduced annual energy consumption by 20% plus lower water usage and waste generation.

Digital Twin communities to work together closely in supporting a circular economy. "The linear 'Take - Make - Dispose' system, which depletes natural resources and generates waste, is deeply flawed & can be productively replaced by a restorative model in which waste does not exist as such but is only food for the next cycle" Ellen MacArthur, Founder, Ellen MacArthur Foundation

Sanofi’s Framingham Lighthouse facility, a digitally enabled, continuous manufacturing facility, is another example cited in the Accenture report. Virtual or digital twins optimize small manufacturing through the use of real-time data capture and analysis. The whole industrial process is digitalized and paperless, and is 80 times more productive than a traditional factory.

As challenges concerning food security and climate change mount for our societies, the need to adopt sustainable economic practices will only increase, thereby creating an opportunity for geospatial and Digital Twin communities to work together closely in supporting a circular economy.

© Geospatial Media and Communications. All Rights Reserved.