“We need to devise innovative and sustainable methodologies to improve efficiency and controls with a high emphasis on ESG and Safety. It is important to bring about a cultural as well as perspective shift in the industry to adopt a digital mindset and make big investments into Industry 4.0 technologies,” says C. Chandru, Chief Operating Officer (COO) – Smelters, Hindustan Zinc, in an exclusive interview with Geospatial World.

In 2022, We want to take the next big strides to continue transforming ourselves into an ever compliant, energy-efficient, water-positive and data-driven organization. Deployment of EV in material handling will be a key focus area for FY 22-23.

I see the post pandemic world to be more inclusive to local vendor base, local communities, and local customers, as industries have realised the importance of creating an impact on the communities they thrive upon.

The pandemic has been nocuous to everyone, more so for an organization like ours which is highly labour intensive and operates in an ever-competitive market. For us, our human resource is our biggest asset, and we are committed to leave no stone unturned to ensure their security and wellbeing.

Now, that the scenario is settling down to the new normal, I realize the pandemic has taught us a lesson the hard way. We need to devise innovative and sustainable methodologies to improve efficiency and controls with high emphasis on ESG and Safety.

We are just at the verge of experiencing the transformation that of Industry 4.0 and AI is going to bring to the Metal and Mining sector.

Since our inception, we have recognized the importance of new technology and have always put it at the forefront of our operations. At a time when these phrases were only buzzwords in the industry, Hindustan Zinc’s mindset included robotics and automation. We were able to build an enabling environment for our business growth by employing best-in-class technologies backed by automation and analytics.

We’ve been pursuing plant operations automation for a long time, and we’re finally reaping the benefits when main plant processes can be controlled remotely with minimal human participation. Since the late 2000s, Hindustan Zinc’s ore beneficiation and smelter operations have used Advanced Process Control to automate majority of mineral processing and metal extraction procedures. These systems have developed from using static model set points to continually updating cloud-based solutions with a continuous stream of data with the introduction of machine learning and artificial intelligence. The plants have been able to run at full capacity while preserving social distance rules because of this.

We are already using robotic arms for our FG handling since quite some time now, which I believe is an industry first, in India.

We are a global organization with Indian ethics and a start-up mindset. The organization had perceived the gravity and value of digitalization and specifically the Artificial intelligence and Machine Learning very early. We developed a progressive framework on how to harness the seamless potential of data and established a collaboration centre and a dedicated digitalization team. We operate out of multiple smelting and mining locations, with a wide array of technologies from across the world. Needless to mention we generate staggering amount of data; all these sources of data were integrated into centralised historians like Pi system and SAP for better collation and analysis of data. We can safely say that Hindustan Zinc was better prepared than other in the industry to adopt digital transformation.

The smelters/ mines of future will be highly safe integrated plants with exceptional levels of situational awareness and process control, with extremely conservative human resource requirements coupled with environmentally sensitive tech like EVs.

We are in a steady transformation from a traditional Mining Metal company to data/technology driven environmentally aware socially sensitive and highly efficient Mining Metal Company.

Unlike sectors such as automobile and FMCG, Mining and Metallurgy has always been mechanized and manually demanding sector due to the type of operations we sustain and environment we operate in. Initially the sector was orthodox, technologies and sensors were not mature enough to be deployed in environments smelters and mines. Simply no sensors would work in a 1100 degree Celsius smelter environment or in the fine dust of a mine.

Along with technology evolution, we have made continuous endeavour, to upgrade to best-in-class systems, like all our smelting units, beneficiation plants and Power plants today run on highly automated and integrated DCS systems, our Finished goods handling is almost manual intervention free.

We are Artificial intelligence, machine learning and mathematical regression based predictive modelling for adding value to safety, in-process control, process monitoring; we plan to use digital twins for advanced process control, optimization, and predictive maintenance.

Since the very nascent stages of deployment of these technologies, we could observe step improvements in our overall energy efficiency, asset availability, metal recovery, inventory management and product quality to list a few.

These systems have given us multiple layers of efficient process control, enhanced safety/production and improved over all working conditions, transparency and optimized man hours/resources required for sustaining operations. Above all it gives us unprecedented levels of situational awareness and data to work upon.

Rapid technological advancements, such as automation, digitization, and electrification, are transforming the metals & mining industry. Autonomous vehicles, remote operation centers, automated drilling and tunnel-boring systems, machine learning, and others are among the new technologies that are altering the industry. Natural resources such as water, soil, and minerals are used extensively in the mining business.

We are in the process of introducing Digital Twins of our Roasters and CPP units which will give us the autonomy to experiment with the process dynamics and process parameters to optimize the process for even higher efficiency and sustainability, without even hindering the wonted operations. What it essentially means is we will be able to optimize our process in such a way that we generate minimum hazardous waste like NOx SOx and fine flue dusts. We are using satellite imagery to map and track our Jarofix dumps.

We have already introduced AI enabled electrically powered mobility solutions inside our mines i.e., all the equipment operational inside our mines will be intelligent electrically powered platforms. These technologies that we are discussing today are just the tip of the iceberg, the prospects are endless.

We need to devise innovative and sustainable methodologies to improve efficiency and controls with high emphasis on ESG and Safety.

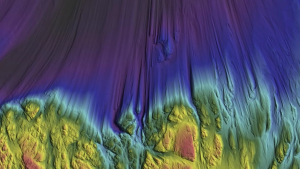

Situational awareness is key to kind of critical operations we manage. Local Intelligence and real time data transfer combined with systems like SAP and Pi system has given us the unprecedented capability to monitor and control our production units, plants and systems from virtually anywhere in the world. Now we can predict potential failures and plan around them to sustain maximum availability of assets. It also reduces the response time in case of any process or safety eventuality. Apps like V-Safe are providing a safe and healthy working condition for our women employees. Satellite imagery and LIDAR technology is useful in efficiently and safely locating and extracting minerals.

The industry is orthodox to changes, the basic principles of smelting and mining have not changed much. The technology is not mature enough for large scale deployment in critical industries like ours. Most of our assets and plants will require high capital investments for upgrading them to Industry 4.0 standards and obviously the terms of returns of investments needs to be figured out.

It is important to bring about a cultural as well as perspective shift in the industry to adopt a digital mindset make big investments into Industry 4.0 technologies.

HZL fundamentally believes in a globally diversified vendor base rather than a coupled supply chain ecosystem, the pandemic has revalidated our faith in our supply chain strategy. I strongly believe there will be a paradigm shift in all verticals of manufacturing towards decoupled, diversified, and resilient supply chain. This will have a positive impact in mining and other industries as we can develop a cost efficient, quality and delivery focused supply chain which accommodates the local vendor base and the global ones.

In case of our mines, Sandvik implemented a major digital transformation at Hindustan Zinc’s Sindesar Khurd (SK) mine, ensuring all essential platforms and infrastructure were in place to deliver world-class safety, efficiency, and productivity. Sandvik provides one of the most extensive digital services to the SK mine with its industry-leading, OEM-independent

OptiMine digital platform. The world-class system integrates IBM Watson IoT and includes OptiMine Monitoring, Location Tracking, Mining Visualization, Scheduler, Task Management, and OptiMine Analytics, among other capabilities for managing subterranean activities.

As far as the digitalization in our smelters is concerned, we have engaged with the technology giants like Siemens, Honeywell, Yokagawa, etc., to develop unparalleled levels of automations in process controls ranging from APCs to fully integrated DCS systems.

We have also nurtured a very flourishing ecosystem of Start-up through our Vedanta Spark initiative when in we are working with Start-up organizations to work on complicated business pain areas. We are working on improving the Finished Zn ingot quality with an AI Image analytics model with a start-up named Algo8.ai. Similarly, we are tracking the Un safe acts and conditions in the plant using an analytics solution with Detect Technologies. On the water management front, we are have developed an automated water management and tracking system with Promethein, which is also a startup.

Digitalization and automation are umbrella terms for a host of advanced technologies and practices that we believe can be the next disruption in the manufacturing industry. We are investing big time into Data Analytics and Artificial intelligence for advanced process control and a data driven decision making process. Simulation models and digital twins gives us the ability to plan our predictive maintenance cycles and deploy efficient process controls for high asset availability and sustain environmentally optimized operations.

The pandemic made us realise that to stay relevant in the future, its high time that we adopt greener and more environmentally sustainable avenues of operations. The new age technologies like EV fleets, AI/ML and the alternate sources of green energy will help us snap the barrier, reduce our carbon footprint and net emissions, making u resilient, sustainable, and better able to cope with market dynamics. I have no apprehensions in saying that we, at HZL, are future-ready.

Director of Geographic Information Systems (GIS) at the Central Informatics Organisation (CIO), Bahrain, Dr. Khalid Abdulrahman Al Haidan, has been selected among the top four global leaders in GIS by the ESRI….

Background With a total food production of 960 million tonnes (MT), the estimated Gross Value Added (GVA) by agriculture, forestry, and fishing to the Indian economy stood at INR 19.48

© Geospatial Media and Communications. All Rights Reserved.